Producing quality green or recycled plastic from captured CO2

eyesonindonesia

Amsterdam, 26 june 2023 – The actual production process may require very specialized equipment and technology that require technical expertise. Some steps involved.

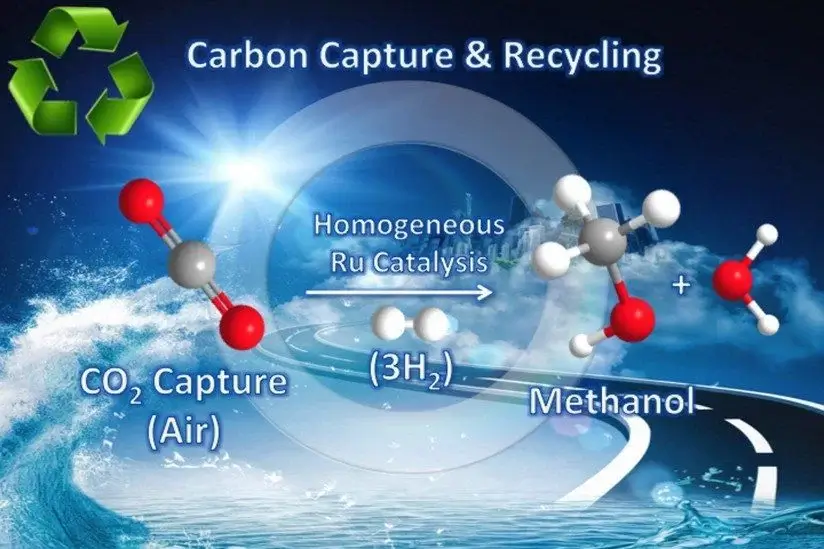

CO2 can be captured from industrial waste streams or directly from the atmosphere using various capture technologies like absorption, adsorption, and membrane separation. After that step the chemical conversion follows.

The captured CO2 can be converted into a range of feedstocks or building blocks like CO, H2, and CH4 using chemical reactions like hydrogenation, electrolysis, and others.

From Building Blocks to Plastic Products: The Polymerization Process

Polymerization is the next step. It involves and means: that the building blocks can be polymerized or combined to produce different plastic products like polyethylene, polystyrene, and others using catalysts in the presence of heat and pressure.

But quality control is always paramount. There checks must be carried out at every stage of the production process to ensure that the final product is of high quality and meets the required specifications.

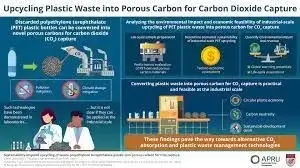

Followed by the incumbent recycling process itself. After producing the plastic product, the company can subject it to recycling processes such as mechanical, chemical, or thermal recycling. This extends the product’s life cycle and reduces its environmental impact.

Overall, producing quality green or recycled plastic from captured CO2 requires a combination of innovative chemistry, sustainable technologies, and quality control checks to ensure that the final product meets the desired environmental and quality standards.